Quality Assurance/Quality Control

“EXCELLENCE EXECUTED”

OBJECTIVE OF THE VERTICAL

- Spread awareness of quality & safety best practices and need for quality in construction

- Establish planned quality & safety as a widely accepted practice for cross construction sites

- Bring best of breed practices in industry to easily practicable form

- Leverage knowledge repository of ANP to deliver high quality services

APPROACH

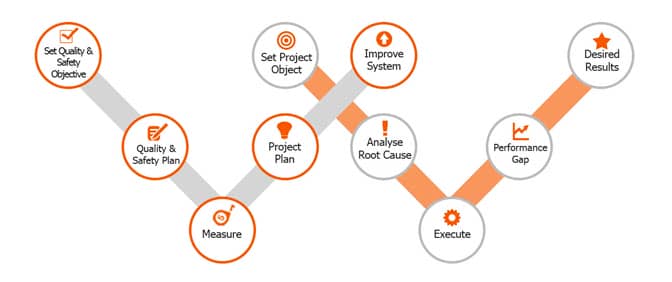

Our approach as captured in “Double V” model shown above focuses on:

“Based on the Plan-Do-Check-Act-Improve cycle, this system ensures Action Learning by the organization audited and provides lasting improvements.”

- Planning quality & safety alongside the project at each major stage of the project

- Ensure quality & safety is given due recognition and is built in to the system ab initio

- Pre-setting quality & safety benchmarks for specifications, work performance and workmanship requirements

- Monitoring work against these metrics

- Reporting holistically on preventive action, corrective action and innovative practices

- Recommending changes based on the root cause analysis of vital issues

- Protectively aim at preventive care rather than finding a cure

ENGAGEMENT MODEL

The various engagement models envisaged are:

- Comprehensive service across project life cycle covering

- Quality & Safety Planning

- Metrics identification

- Reporting on preventive, corrective and innovative actions

- Root cause analysis and recommendations for systemic improvements

- Conducting pre-delivery inspections

- Providing Quality & Safety Planning and Operating Procedure tailoring prior to execution

- Conducting Quality & Safety audits

- Conducting Pre-delivery inspections

HOW ARE WE DIFFERENT?

“Ultimately the objective is to ensure fitness of purpose and fitness of use“

- We use our vast experience across all domains-civil, electrical and mechanical

- We leverage upon years of experience that we have gathered by working on different projects

- We focus on prevention rather than cure

- We leverage upon our vast repository of standard operating procedures for all disciplines

- We make use of case studies for improving quality across many construction sites

- MINIMAL ON SITE DEPLOYMENT – HIGHLY KNOWLEDGE DRIVEN

- RELATIVELY LOW COST TO CUSTOMER

- HIGH VALUE ADDITION